Disrupting the Medical Industry with 3D Medical Models

The Story

Dr. Justin Sutherland began his medical career at McGill University, obtaining his MSc in Medical Physics. He later went on to complete his PhD at Carleton University. He completed his residency in radiation oncology physics at the Ottawa Hospital and began practicing as a physicist.

Justin became fascinated with virtual reality (VR) at an early age after seeing early technology models at amusement parks. As an avid video game enthusiast, he developed a keen interest in experimenting with VR systems from a gaming perspective. He dreamt of a way that virtual reality technology could make these superpowers a reality for modern healthcare professionals.

Dan La Russa, a medical physicist and colleague, crossed paths with Justin when they worked together at the Ottawa Hospital. Dan also shared a passion for education and assisted as a radiology and radiation oncology professor at the University of Ottawa.

Together, they founded Realize Medical Inc, a startup delivering the first platform for building 3–dimensional (3D) medical models based entirely in virtual reality. They hoped to positively disrupt the medical industry in terms of how healthcare professionals view medical images and how they interact with the information. These innovators were on a mission to improve the advanced 3D modelling, visualization, and communication tools that enhance patient care.

The Challenge

Physicians, surgeons, and other healthcare professionals strive to improve patient care; however, time spent with their patients is limited. The health tech and medical device industries are finding innovative and adaptive solutions to create individualized treatment plans for patients.

Healthcare professionals rely on medical images like CTs and MRIs to make informed decisions when creating treatment plans. The perspective of a 3D form (like an organ, for example) portrayed through a flat image is problematic because they‘re 2–dimensional (2D) representations, so doctors have to scroll and piece together conclusions from multiple reports at once. When making decisions that could impact patients‘ lives, it‘s not an optimal resource.

Imagine working as a mechanic and not being able to look under the hood of the vehicle. Although you may have pictures of the car parts, you’re limited to one perspective. You can view the pieces in isolation, but it isn’t easy to understand how everything fits and works together. These challenges restrict your ability to diagnose what is wrong with the vehicle and formulate an effective action plan. This is the dilemma that healthcare professionals navigate every day. Fragmented slices of the body are viewed from one limited orientation.

Conventional 2D monitor displays will soon be obsolete and replaced with mixed reality tools. But crafting patient-specific 3D models from clay or other material is time–consuming, tedious, and not viable. The need to have a form to which doctors can manipulate orientations and better understand the problem remains present.

The Solution

Envision a world in which physicians, surgeons, and other healthcare professionals had x-ray vision. They could look inside their patient to view the specific area as a 3D form and base their decisions on the most accurate information. Justin, Dan and their team strove to create a medical device that does just that.

Elucis is the world’s first VR platform designed to create 3D medical models. This innovation provides surgeons and healthcare professionals with a radically new way to produce 3D medical content interactively. This medical device makes it effortless to translate medical images into 3D models that can later be 3D printed or used in mixed reality systems. In other words, this technology allows physicians to not only make 3D models of their patients in a way that is efficient and easy, but they can also manipulate these models using virtual reality.

Doctors can use a hand-held stylus on a writing surface to engage with the 3D models virtually. By doing so, healthcare professionals can iterate their approach to a proposed surgery or treatment plan. For example, a physician can 3D model their patient‘s heart promptly and develop a patient-specific treatment plan. The results or findings can easily be shared with colleagues to gain a second opinion.

Realize Medical Inc’s mission is “to provide healthcare professionals with the 3D modelling tools they need to improve patient care and education. By designing our product specifically for VR, we enable surgeons and healthcare professionals to quickly find what they‘re looking for, understand complex 3D anatomy, and simplify the communication of their findings with their peers.”

Invest Ottawa

The road to entrepreneurship began for Justin and Dan at Invest Ottawa (IO) in the summer of 2019 when they applied and were accepted into the Pre-Accelerator program (Cohort 4). This program provided them with a 10-week boot camp designed to help Ottawa’s entrepreneurs at the early stages of building a tech or tech-enabled startup. The goal of the program was to validate their problem-solution and solidify their business foundations.

Working within one of Ottawa‘s most desired tech startup community lends itself to daily networking activities: meeting other startup founders, brainstorming solutions to problems, introductions to the stakeholders and influencers in Ottawa‘s tech startup ecosystem. Additionally, the in-house Market Insights (MI) team worked directly with Justin and Dan to equip them with industry–specific market research and analysis. The MI team also curated leads to target for business development.

This program guided the founders throughout their journey using various resources such as one-on-one mentorship by trusted professionals in finance, fundraising and life sciences. With the guidance of IO mentors, Realize Medical began its pilot trial initiatives and reported key insights.

Milestones accomplished through engagement with the program include:

- Secured partnership with Logitech (an international computer software manufacturer);

- Secured its first paid customer, the Michener Institute;

- Secured $30K grant from OCE and $10K from IRAP to complete key developments; and

- Beginning seed fundraising efforts with a minimum target of $1M.

The IO 5G program provided state-of-the-art 5G infrastructure and technology that enabled the pre-commercial development, testing and demonstration of tech products, like Elucis. There are many advantages for emerging tech companies to develop with 5G, as consumers experience faster data rates, larger data volumes, lower energy consumption, etc. This program allowed Justin and Dan to build their product to be compatible with the most current technology, giving them a competitive edge while positioning their product ahead of the curve.

Justin and Dan joined the IO Health Tech Pre-Accelerator (pilot) program in Winter 2020 and rapidly and systemically accelerated their startup growth. They participated in two of Invest Ottawa‘s pitch competitions and pitched their business to a panel of judges and investors. The aspiring entrepreneurs wowed crowds of over 200 viewers with their innovative product design. Their business opportunity was recognized, and Realize Medical won the top prize of Best Pitch at both events.

Bayview Yards Prototyping Lab (BYPL)

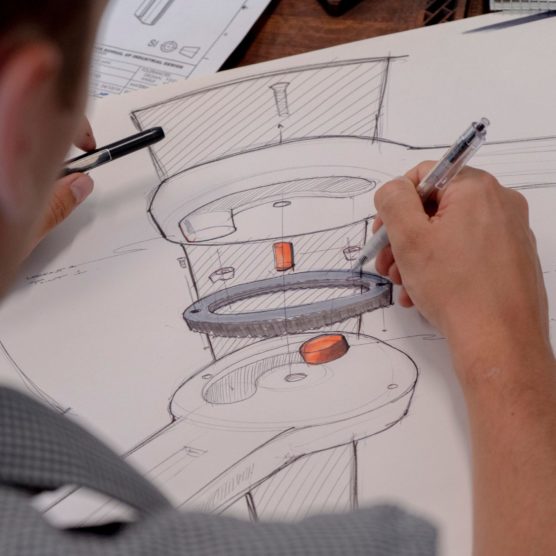

Realize Medical engaged Bayview Yards Prototyping Lab (BYPL) team of experts throughout every phase of their prototyping journey. For their intended user to interact with the VR technology, they needed to design a hand–held stylus pen that was not currently available within the market. Justin and Dan approached BYPL with their idea. They had made a low budget rough model of their idea, but with the help of BYPL, they were able to engineer and 3D print an early stage proof of concept prototype that was polished and professional. With this prototype in hand, they felt confident presenting their idea to media, investors, etc.

He notes, “when we were just starting out, we had a duct tape pen that we assembled ourselves that didn‘t present the best version of our concept to the doctors who were testing our products.” He went on to say, “the Bayview Yards Prototyping Lab helped us a lot. We came to them and asked them if they could make a stylistic version for us, and they designed a few great options. We‘ve been asking them to make more and more as we‘re giving them to early beta customers, and we want investors and prospective clients to hold a tangible example of our product.“

The innovators also benefited from access to in-house virtual reality and 3D printing technology. Justin states that “using the Lab was great because it was local, convenient, and a start-up-friendly service. There was an immediate element of trust because of the association with the Invest Ottawa brand. I didn‘t have to worry about the possibility of being taken advantage of. They focused on meeting my needs efficiently using a collaborative process.“ BYPL proved to be an invaluable asset, and the team continues to partner with BYPL on an ongoing basis.

BYPL worked to consolidate their clients’ ideas and create a detailed 3D model. The model represented the intended size and manufacturing considerations of the anticipated final design. The Prototyping Design Package utilized a systematic process to validate their idea and build a functional prototype. By 3D printing their prototype through an iterative process, they experimented with different materials and design adaptations, which not only optimized quality and performance but reduced R&D risk and expenses.

[Caption: Dr. Justin Sutherland of Realize Medical describes how the Bayview Yards Prototyping Lab helped him design a proof of concept prototype and how this support led to his startup becoming more customer, market, and investor–ready.

The Update

By embracing Bayview Yards, Ottawa’s one-stop business acceleration shop, Realize Medical gained access to the ecosystem of services and programs designed to support entrepreneurs. BYPL team successfully created a proof of concept prototype that was a critical component in securing their first revenue-generating client. And Invest Ottawa facilitated their partnership with Logitech that will allow them to advance their product offering.

With these advancements, Justin and Dan continue to refine their product offering and seek early beta testers within Canada and the United States. Today, they have a team of four full-time employee, three part-time employees, and one employee on a contractual basis; among which are software developers and business development leads. Justin attributes much of the success his brand has experienced to the services offered through IO and BYPL.

Want to read more SUCCESS STORIES?

Join our mailing list for email updates on updates, community news, new services, promotions, and more.