An Update: How the Prototyping Lab is Delivering on Their Mission to Support Innovation and Entrepreneurs

Keep Prototyping

These are trying times, yes, but this city is resilient, especially its innovators. Entrepreneurs know that now is not the time to put their foot on the brakes but to continue to drive ideas and product development forward. For our clients, this means they need to proceed with turning their concepts into prototypes.

Proof-of-concept prototypes are critical to validating new products, which helps reduce risk, shorten time to market and increase investment potential.

We’ve recently heard from many entrepreneurs that they’ve moved their work to remote, and so have we. Transitioning a team to a different style of working is challenging under any circumstances, and making it happen overnight – that’s an even bigger feat. But we’ve been determined.

How We Adjusted Our Operations

The Bayview Yards Prototyping Lab team has the expertise and capabilities to support clients through any or all phases of a project from design, build and launch. The sharing of ideas and collective brainstorming is a central part of what we do. Facilitated collaboration has always been an essential component of our workflow.

Before the pandemic, we would share a physical space as a team – and with clients – to engage through sketching, brainstorming, mock-up building (we often use Lego or cardboard to co-create). In response to the work-from-home order, we migrated these efforts to a digital platform.

To maintain our collective problem-solving approach, the team keeps virtual meetings consistent. We all check-in daily. During that time, we problem solve, brainstorm, and work together on our various projects of focus.

The problems we work to solve are our clients, so developing a trusted relationship with them is critical, and this takes time. We have increased our touchpoints with them and use digital tools to stay connected. The frequent progress updates and collaborative design sessions keep us aligned with their vision. It’s a different way of working together, but it is working.

Our team does miss seeing client’s early low-fidelity homemade prototypes and hearing them share their development process firsthand.

Creative Solutions – Digital Tools

How is it going?

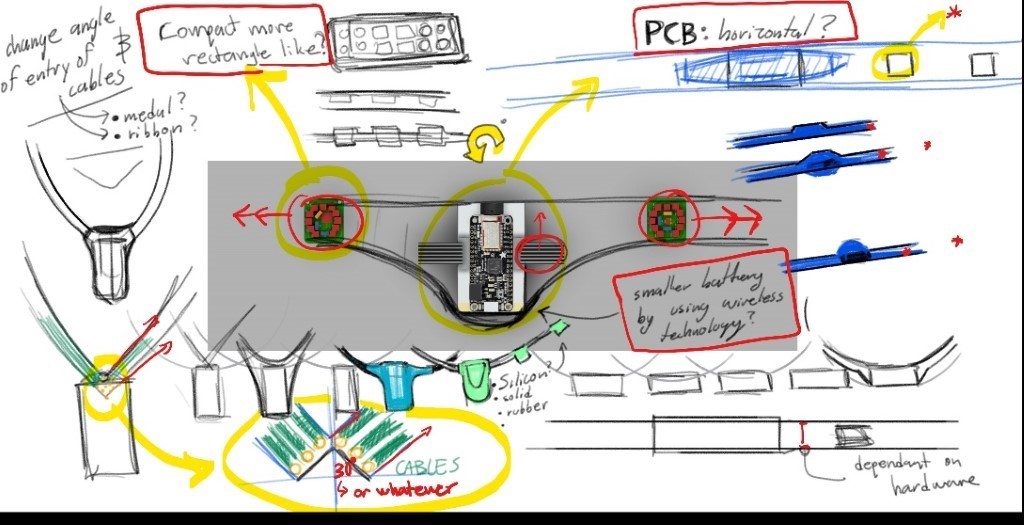

The ability to collaborate live through interactive online applications has enabled us to continue developing designs through teamwork. Sharing screens and using digital whiteboards (Fusion 360 is one software our team uses) to create basic sketches has proven to be as effective as collaborating in person. A great example of this is the fact that rough digital illustrations formed during virtual meetings have become a cornerstone in our development process – they allow our ideas to be interpreted by others without having to describe it in perfection.

Screen sharing is a lifesaver. By sharing our screen with clients, we can directly address topics related to features, components or any other type of design request. By viewing the designer’s work in real-time, we’ve found clients feel more engaged, and that makes the exploration of ideas more effective.

Industrial Design – from Home

Equipment on the Move

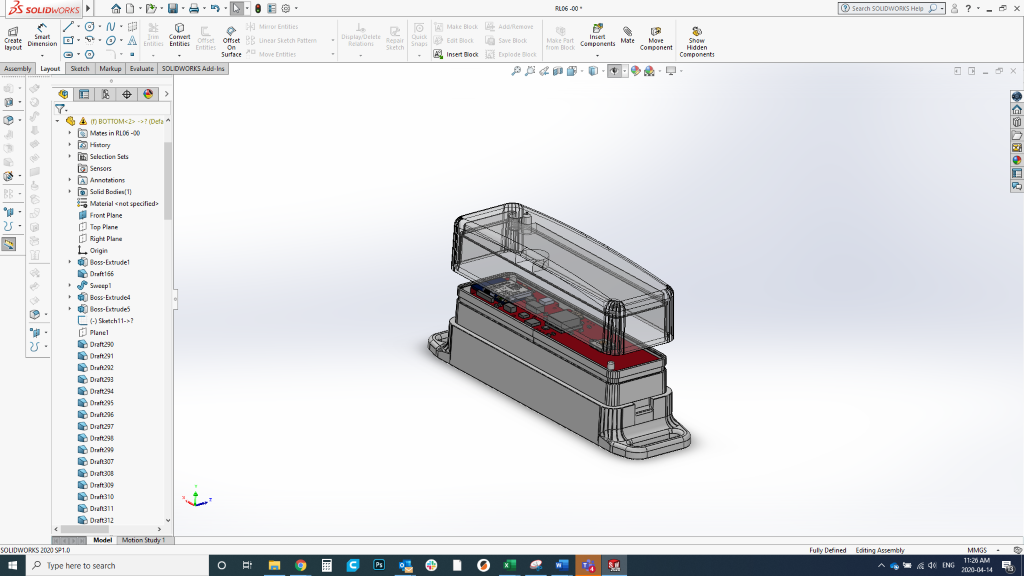

Much of the work we produce is physically possible because of various tools and equipment we have on-site. Therefore, our favourite desktop tools had to be more to new offices – home!

Thanks to the compact size of the Formlabs and its components, Pablo has been able to continue developing prototypes by relocating the 3D printer to his home office. There is a range of materials available to work with for early-stage iterations for visual effect and developing engineering tolerances and draft products.

Electronics

The world has seen innovative solutions come to the table that won’t only help during these trying times but will benefit health and wellness well beyond today. You can see this in the smart wearables industry. In terms of electronics, generally, seeing what’s introduced is inspiring.

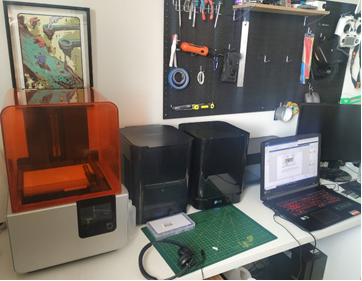

Erin Kennedy, Electronics Designer, has assembled a lab from her home, equipped with two 3D printers — one of which was repurposed and is now functioning as a digital optical scanning microscope.

“We brought the Bantam Tools mill so that progress can continue on milling circuit boards. There’s a myriad of the internet of things (IoT)-connected devices, along with a Geiger counter and a map of Mars – in case I get lost”, says Erin. Her passion for helping our clients realize their vision continues to fuel her efforts to advance projects during this time.

It’s clear that for entrepreneurs, there is an opportunity to create and develop new ideas — and the Prototyping Lab is here to support you throughout that process. Our doors may be closed, but we’re still able to help clients with their electronics design, prototype fabrication, and firmware code.

Digital Media And design

Petr Maur, Graphic Designer, Videographer, and Photographer, continues to communicate client stories through various mediums. His most recent work connects the viewer to the humanity of the pandemic by documenting the surrounding neighbourhood as the community practices social distancing. Follow @petrmaur to see more of his work.

Between client projects, our Mechanical and Fabrication team, Scott Rathwell and Tom O’Leary (aka Tick Tock Tom) are upgrading their certifications on our various tools and equipment, and their annual health and safety training. They are also organizing the shop for maximum efficiency, preparing to welcome our clients back on site.

To keep us all organized, Alanna Hlavacek, our process ninja, has been managing the logistics of getting parts and materials to various locations, as well as managing virtual client consultations and advice.

I am so proud of how my team has adjusted and still come together to lift, catch and challenge each other through this pandemic. We continue to provide design and fabrication services so innovators can get their products into their hands for testing.

Supporting community impact projects

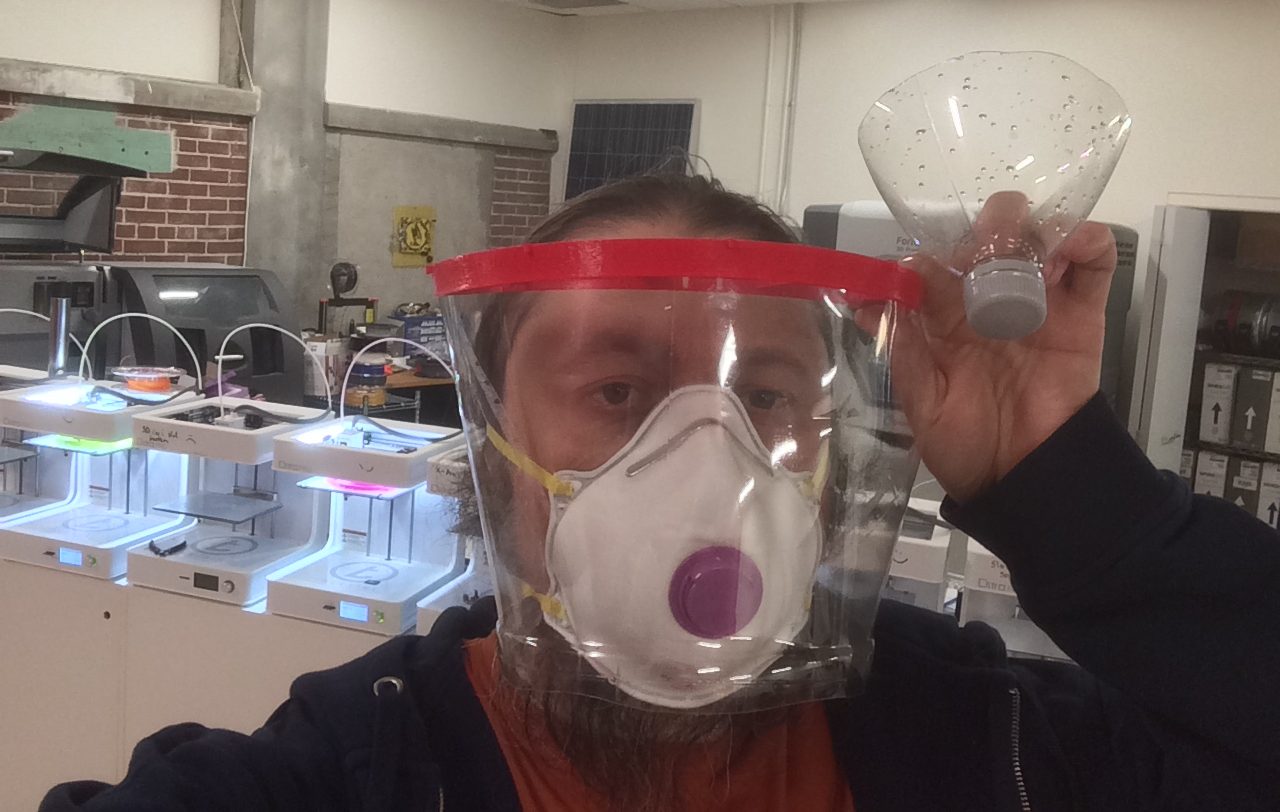

Our Fabrication shop has remained open for critical support on a limited basis. We are supporting COVID-19 community impact projects such as the printing of headpieces for face shields. Our team is available to collaborate with companies who are developing technologies to respond to COVID-19.

Working with @UOMakerspace, @HHOttawa & #OttCity‘s maker community, our 3D-printers are working round the clock to make face shields for front line health professionals 👩⚕️

Need help making parts for protective equipment? Contact us: https://t.co/AoSq5GTwZy #OttBiz #COVID19 pic.twitter.com/1l5IRurqO0

— Bayview Yards (@Bayview_Yards) April 6, 2020

AVAILABLE SERVICES

The Prototyping Lab is committed to serving innovators and entrepreneurs. Do you have a project? Connect with our team to start a dialogue. Our designers would be delighted to schedule consultations via a web conferencing tool. We are here to discuss your needs and possible outcomes.

To see a full list of the services available, download our informative PDF.

Want to read more?

Join our mailing list for email updates on updates, community news, new services, promotions, and more.

About the author

Joanne Gardner is the Director of Advanced Manufacturing and Digital Media Lab, GovTech Prototyping. She is an accomplished, versatile, and driven leader with a proven track record and excellent knowledge of government, charitable and corporate business practices. With a passion for building sustainable communities and social justice, Joanne has demonstrated experience in developing creative and effective solutions to diverse and complex business problems, while leading innovative strategic programs with a focus on both social and financial return on investment.

Joanne Gardner is the Director of Advanced Manufacturing and Digital Media Lab, GovTech Prototyping. She is an accomplished, versatile, and driven leader with a proven track record and excellent knowledge of government, charitable and corporate business practices. With a passion for building sustainable communities and social justice, Joanne has demonstrated experience in developing creative and effective solutions to diverse and complex business problems, while leading innovative strategic programs with a focus on both social and financial return on investment.